machine optimization through small reduction motors-凯发k8天生赢家一触即发

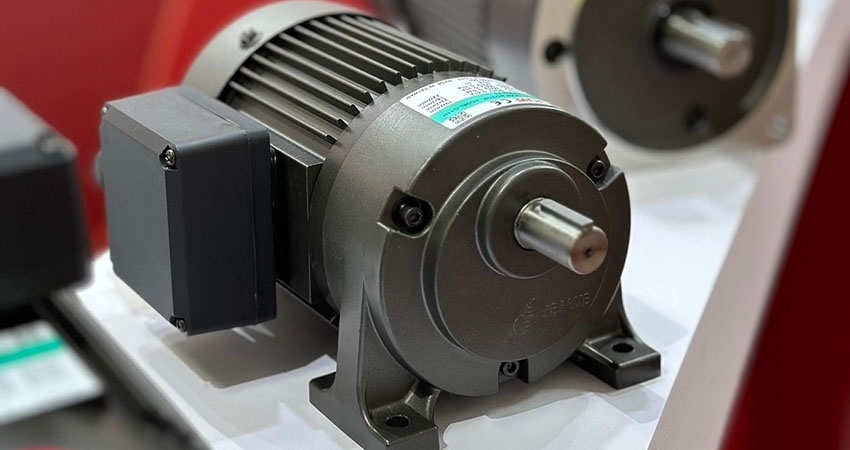

small reduction motor is a compact electromechanical device that combines an electric motor and a speed reduction system. the electric motor provides the initial rotational force, while the speed reducers or gear system reduces the speed and increases the torque output. small reduction motors are integral to modern industry and daily life because they enable the functionality of countless devices and systems we rely on, from smartphones to factory automation. their combination of power, precision, and compactness makes them indispensable in today's technological landscape.

〈read more: what are speed reducers? how do they work?〉

principles of small reduction motors

when electricity is supplied to an ac motor or a dc motor, it creates a magnetic field that interacts with either permanent magnets or electromagnets, causing the rotor to spin. the motor's output shaft is connected to a speed reduction system or series of gears. these speed reduction systems reduces the speed of the final output shaft while increasing torque.features of small reduction motors

compact size

their small form factor allows for miniaturization of devices and equipment.efficiency

small reduction motors can provide high torque at low speeds and power consumption (compare to higher output motor without speed reducer), making them energy-efficient in many applications.reliability

well-designed and quality small reduction motors can operate for extended periods with minimal maintenance.affordability

mass production has made them cost-effective for widespread use in machinery and household devices. they are essential components in many automated systems, driving industrial progress.easy maintenance

quality small reduction motors are built to withstand continuous operation and easy to maintain because of its sealed and modular design, relatively simple internal structure and integrated lubrication.types of small reduction motors

small reduction motors, also known as gear reduction motors, come in several types. here's a concise overview of common types:spur gear and helical gear motors

series of different size spur or helical gears assembly are used to reduce the speed of electric motors while increasing torque at the output shaft. these gear motors are used in a wide range of industrial and commercial sectors including food processing, conveyor belts, grinders, mixers, ventilation and cooling devices, vending machines, cup sealers.worm gear motors

a worm gear motor is a type of electric motor combined with a worm gearbox, consists of a screw-like gear (worm) that engage a spur or a helical wheel, to transmit power and torque. worm gear motors are used in applications where a relatively low speed and relatively large output torque are required, such as foodstuff, packaging equipment, conveyors. they are often used in lifts, elevators and hoists because of their self-locking and holding ability without requiring an external brake.planetary gear motors

a planetary gear motor combines an electric motor (usually a servo motor) with a planetary gearbox. the planetary gearbox reduces the motor's speed while increasing its torque output. the internal structure of the planetary gearbox is an epicyclic gear train, the operation of such gear set looks similar to our planetary solar system and that is how it is named, a planetary gearbox. planetary gear motors are frequently chosen for high precision position control applications such as robotics (joint movements), cnc machines (controlling tool positions), agvs & amrs (drive module) due to several key characteristics of low backlash, excellent repeatability, high torsional stiffness and high efficiency.applications of small reduction motors

automation

small reduction motors are widely used in automation equipment and machinery due to their ability to provide high torque at low speeds. here are some areas where they're commonly employed:- packaging machinery. to control feeding rates, operate sealing mechanisms or to drive sorting systems.

- food processing equipment. to power mixers, blenders, cutting and slicing machines, filling and dispensing systems.

- warehouse automation. small reduction motors are used in automated storage and retrieval systems (as/rs) to control the crane or lift mechanism for accessing different levels of storage or to drive the carriage along racks for item picking and placement.

- agvs & amrs. small reduction motors are used in automated guided vehicles (agvs) and autonomous mobile robots (amrs) to control movement and steering, to raise and lower carried loads.

home appliances

there are common characteristics across these applications like typically small and energy efficiency, quiet operation, speed control, durability, cost-effectiveness and safety.- washing machines. a reduction motor controls the drum rotation speeds for washing, rinsing and spin cycles. a smaller reduction motor operates the pump that drains water from the machine.

- coffee machines. a small reduction motor powers the grinding mechanism in coffee machines with built-in grinders. a small reduction motor drives the pump that creates pressure for brewing in espresso coffee machines.

- electric curtains. small reduction motors are required to provide smooth and gentle opening and closing movement of the curtain at adjustable speeds.

medical and laboratory equipment

- small reduction motors are used in centrifuges to drive the rotor at precise speeds, to control acceleration and deceleration of centrifuges and allow for programmable speed profiles for different separation protocols.

- automated sample handlers. small reduction motors are used to control carousel or conveyor system for sample positioning.

robotics

- robotic picking and placing systems require high reliability, accurate positioning and smooth movement features of small reduction motors to control each arm joint, to operate grippers, suction cups, or other picking and placing mechanisms.

- palletizers and depalletizers. small reduction motors are used to control mechanisms that arrange items into layers, to raise and lower pallets during the stacking process, and to manipulate items or entire layers of products.

industrial applications

- printing and labeling machines. small reduction motors are used in paper feeding, print head positioning and label applicators.

- textile machinery. small reduction motors are widely used in textile machinery such as yarn winding machines, weaving and knitting machines, fabric cutting equipment, sewing machine feed mechanisms, and other textile processing equipment due to their robust construction, high reliability, and ease of operation.

- vending machines. small reduction motors provide the reliable power to operate the spiral or belt racks that dispense products, and to operate cooling fan systems.

〈read more: what are speed reducers? how do they work?〉

choosing small reduction motors

when choosing small reduction motors, several key criteria should be considered:1. output speed and torque

- determine the required output speed (rpm) and torque for your application.

- consider the gear ratio needed to achieve the desired output.

2. input power and efficiency

- calculate the input power required based on the output requirements.

- look at the motor's efficiency to ensure it meets your needs.

3. size and weight

- consider space constraints in your application.

- evaluate if the motor's weight or volume is suitable for your design.

4. operating voltage and current

- ensure the reduction motor is compatible with your power supply.

- check the current draw to size your power system appropriately.

5. duty cycle

- determine if the reduction motor will run continuously or intermittently.

- choose a reduction motor rated for your expected duty cycle.

6. environmental factors

- consider temperature, humidity, dust, and other environmental conditions.

- select a reduction motor with appropriate protection ratings (e.g., ip rating).

7. noise and vibration

- if noise is a concern, look for reduction motors designed for quiet operation.

- consider vibration characteristics, especially for precision applications.

8. lifespan and reliability

- look at the expected lifespan of the speed reducer and motor. for example, brushless motors typically have longer lifespan than brushed motors due to less mechanical wear. some speed reducers have service-life lubrication instead of regular maintenance.

- consider the reliability of different motor types and brands.

9. control requirements

- determine if you need precise speed control or position feedback.

- consider compatibility with your control system.

10. cost

- balance performance requirements with budget constraints.

- consider both initial and long-term maintenance costs.

11. manufacturer support and availability

- choose motors from reputable manufacturers with good technical support.

- ensure long-term availability of replacement parts.